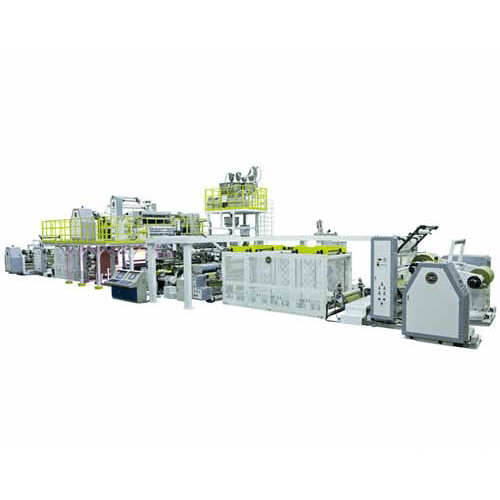

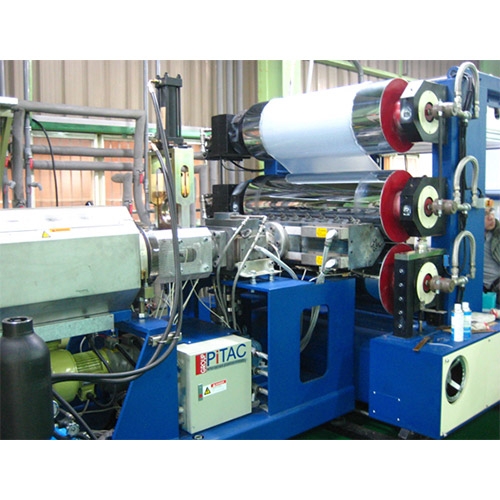

Co-Extrusion Lamination Machine for Thick PET Sheet

Categories : Extrusion Lamination Machines

FKI offers the most advanced and adaptable extrusion system lamination machines for various applications, such as for flexible packaging films like: BOPP, BOPET, CPP, Nylon and aluminum foil, or for craft paper, release paper, tissue paper, cardboard paper, woven fabric, etc. The workable coating materials that can be extruded are LDPE, PP, PEVA, EVA and Surlyn, etc.

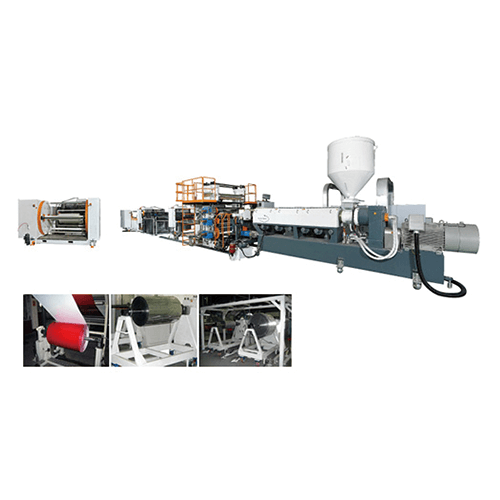

PET Strapping Band Extrusion Line (JC-SPET Series)

Categories : Tape Extrusion Machines

Our JC-SPET Series of strapping band extrusion lines utilize the latest extrusion technology to produce PET strapping bands from 100% treated PET bottle flakes. The resulting straps possess tensile and breaking strength comparable with steel bands, offering a safer, economical, environmentally-friendly solution for medium- to heavy-duty applications, such as securing bricks, tile, cotton bales, and lumber.

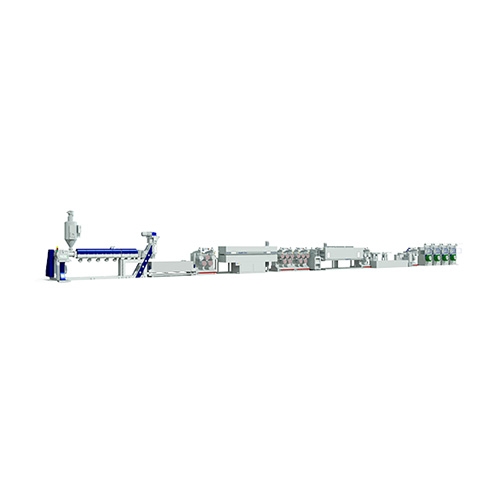

Rigid Sheet Extrusion Line

Categories : Film and Sheet Extrusion Lines

1. Extruder is driven by AC Inverter duty motor, with excellent efficiency and lowest power consumption. 2. Extruder hopper with low-level sensor work with auto-feeder will keep material in stable supply. 3. Hydraulic driven screen changer avoid any particle goes to melting pump & flat-die. 4. Melting pump with accurate rotation control, keeps the material flow stable. 5. Extruder & melting pump speed is working on pressure synchronized controlling system.

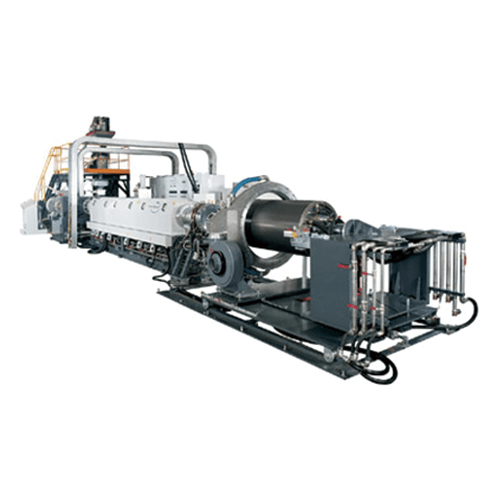

Foam Sheet Extrusion Line

Categories : Film and Sheet Extrusion Lines

Foam Sheet Extrusion Line Features : With proper mixing of melted resin & blowing agent, provides most homogeneous mixing. Accurate blowing agent injecting quantity and temperature control to stabilize the foaming process. High level safety control, system will be shut down automatically when extruder motor failure or high pressure.